Likristale tse kang Nale tsa Mullite tse fanang ka ntlha e phahameng ea ho qhibiliha, katoloso e tlase e ka khutlisetsoang ea mocheso le khanyetso e ntle ka ho fetesisa ea mocheso bakeng sa Mullite e Fused.

- Corundum mullite

- Mullite e kopaneng ea boleng bo holimo

- Mullite e kopantsoeng ka motlakase

Tlhaloso e Khutšoane

Fused Mullite 75

| Lintho | Yuniti | Index | E tloaelehileng | |

| Sebopeho sa lik'hemik'hale | Al2O3 | % | 73.00-77.00 | 73.90 |

| SiO2 | % | 22.00-29.00 | 24.06 | |

| Fe2O3 | % | 0.4 max(Likotlo 0.5%max) | 0.19 | |

| K2O+Na2O | % | 0.40 max | 0.16 | |

| CaO+MgO | % | 0.1%max | 0.05 | |

| Refractoriness | ℃ | 1850 mets | ||

| Boima ba bongata | g/cm3 | 2.90 mets | 3.1 | |

| Likahare tsa mohato oa khalase | % | 10 max | ||

| 3Al2O3.2SiO2Mokhahlelo | % | 90 mets | ||

F-Fused;M-Mullite

Fused Mullite 70

| Lintho | Yuniti | Index | E tloaelehileng | |

| Sebopeho sa lik'hemik'hale | Al2O3 | % | 69.00-73.00 | 70.33 |

| SiO2 | % | 26.00-32.00 | 27.45 | |

| Fe2O3 | % | 0.6 max(Likotlo 0.7%max) | 0.23 | |

| K2O+Na2O | % | 0.50 max | 0.28 | |

| CaO+MgO | % | 0.2% boholo | 0.09 | |

| Refractoriness | ℃ | 1850 mets | ||

| Boima ba bongata | g/cm3 | 2.90 mets | 3.08 | |

| Likahare tsa mohato oa khalase | % | 15 max | ||

| 3Al2O3.2SiO2Mokhahlelo | % | 85 mets | ||

Mokhoa oa Tlhahiso

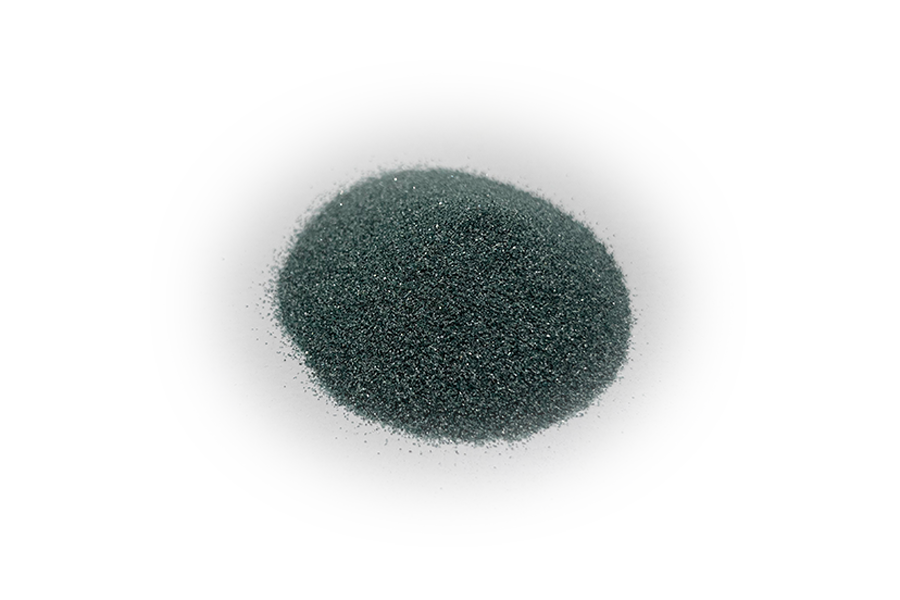

Fused Mullite e hlahisoa ke Bayer process alumina le lehlabathe le phahameng la quartz ha e ntse e futhumala ka seboping se seholo sa motlakase sa arc.

E na le litaba tse phahameng tsa likristale tsa mullite tse kang nale tse fanang ka sebaka se phahameng sa ho qhibiliha, katoloso e tlase e khutlisetsoang ea mocheso le ho hanyetsa ka mokhoa o tsotehang ho ts'oenyeha ha mocheso, ho senyeha ha moroalo, le ho bola ha lik'hemik'hale ka mocheso o phahameng.

Kopo

E sebelisoa haholo e le lisebelisoa tse tala bakeng sa li-refractories tsa maemo a holimo, joalo ka litene tsa lesela ka seboping sa sebōpi sa khalase le litene tse sebelisoang seboping sa moea o chesang indastering ea tšepe.

E boetse e sebelisoa indastering ea sebōpi sa Ceramic le petrochemical le lits'ebetso tse ling tse ngata.

Lichelete tsa Fused Mullite li sebelisoa ho li-coatings tsa Foundry bakeng sa ho hanyetsa mocheso oa mocheso le thepa e se nang metsi.

Likaroloana

• Botsitso bo phahameng ba mocheso

• Katoloso e tlase ea mocheso e khutlisetsang morao

• Ho hanyetsa tlhaselo ea slag ka mocheso o phahameng

• Motsoako o tsitsitseng oa lik'hemik'hale

Mullite, mofuta ofe kapa ofe oa liminerale tse sa tloaelehang tse nang le silicate ea aluminium (3Al2O3 · 2SiO2).E thehiloe ka ho chesa lisebelisoa tse tala tsa aluminosilicate 'me ke karolo ea bohlokoa ka ho fetisisa ea li-whiteware tsa ceramic, li-porcelain, le lisebelisoa tse sireletsang mocheso o phahameng le tse refractory.Lintho tse entsoeng, tse kang mullite, tse nang le karo-karolelano ea alumina-silica ea bonyane 3: 2 e ke ke ea qhibiliha ka tlase ho 1,810 ° C (3,290 ° F), athe tse nang le karo-karolelano e fokolang li qhibiliha mocheso o tlase ho 1,545 ° C (2,813 ° C). F).

Mullite ea tlhaho e fumanoe e le likristale tse tšoeu, tse telele Sehlekehlekeng sa Mull, Inner Hebrides, Scot.E 'nile ea hlokomeloa feela ka har'a li-argillaceous (clayey) tse kopantsoeng ka har'a majoe a sa tsitsang a igneous, boemo bo bontšang mocheso o phahameng haholo oa sebopeho.

Ntle le bohlokoa ba eona bakeng sa lirafshoa tse tloaelehileng, mullite e fetohile khetho ea thepa bakeng sa lirafshoa tse tsoetseng pele tsa sebopeho le tse sebetsang ka lebaka la thepa ea eona e ntle.Lintho tse ling tse hlahelletseng tsa mullite ke katoloso e tlase ea mocheso, mocheso o tlase oa mocheso, khanyetso e ntle ea ho lla, matla a mocheso o phahameng, le botsitso bo botle ba lik'hemik'hale.Mokhoa oa sebopeho sa mullite o ipapisitse le mokhoa oa ho kopanya li-reactants tse nang le alumina le silika.E boetse e amana le mocheso oo karabelo e lebisang ho thehoa ha mullite (mullitisation mocheso).Lithempereichara tsa mullitisation li tlalehiloe li fapane ka likhato tse makholo a 'maloa tsa Celsius ho latela mokhoa oa ho kopanya o sebelisitsoeng.